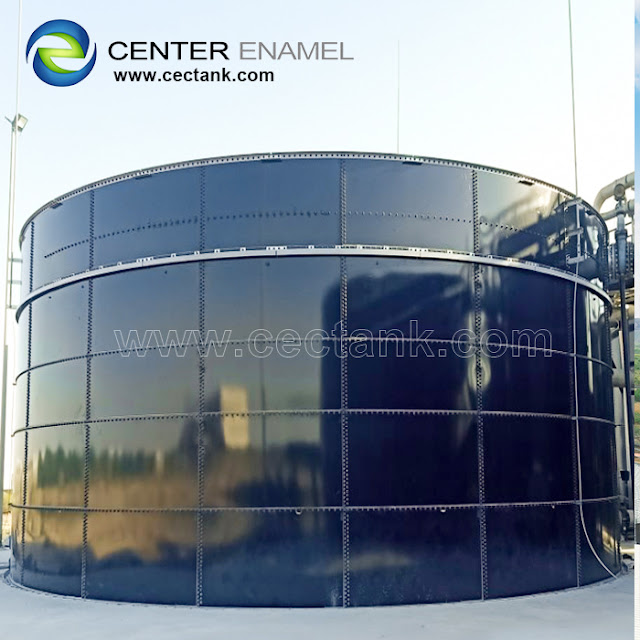

Glass Fused To Steel Potable Water Tanks

Glass Fused to Steel POTABLE WATER TANKS Glass Fused to Steel Potable Water Storage Tank includes several indoor, outdoor and multi-purpose tanks that can successfully store water in almost any location. Made from glass fused to a steel plate, these tanks have been used for potable water storage, bulk water storage, rainwater collection, fire water supply and more. CUSTOM BUILD As the demand for potable water storage, Center Enamel is gearing up for the anticipated boom in the construction of these storage tanks. We offer process and storage systems designed to meet the specific needs of industrial, commercial and retail facilities. Potable water tanks can store liquid safely and conveniently. Choose from glass fused to steel liquid storage tanks that are corrosion-resistant, lightweight, and durable. Liquid storage tanks mainly consist of glass fused to steel plates. After firing at 820°C-930°C high temperature, the molten glass reac...